Heat Treatment Process of aluminium alloy

Solution Heat Treatment

This involves heating of Aluminum alloy to a particular temperature for sufficient time so that the alloying elements go into solid solution and forma single phase. The factors which affect the final properties of the alloy are soaking temperature, soaking time and cooling rate.

The Soaking temperature depends on various phases which are present in alloys. Each phase will dissolve in solid solution at different rates. The soaking time is based on the rate of dissolution of alloying elements into solid solution. It also depends on the conditions under which the alloy is cast. Sand cast parts have coarser structure than permanent mould casting. Hence Aluminium Sand Castings take time for dissolution of phases necessitating longer soaking time.

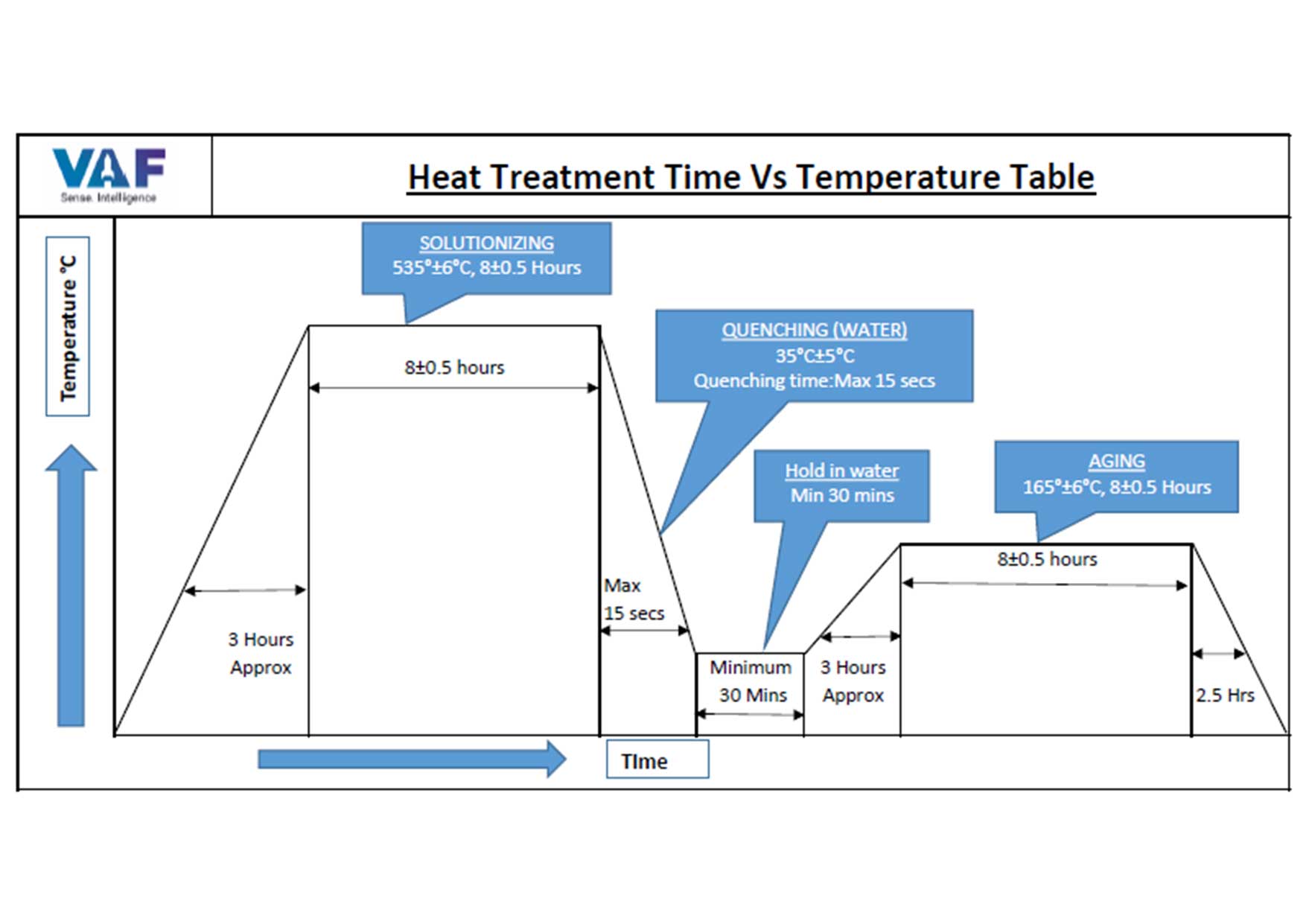

Commonly used T6 Heat Treatment Process:

- Solutionising : Keep in furnace at 525 Deg Celsius for 8 Hrs.

- Quenching : Sudden Quenching in Water at 30 Deg Celsius.

- Natural Ageing : Upto 5 Hrs

- Precipitation : Keep in furnace at 165 Deg Celsius for 8 Hrs.

- Hardness to be achieved between 80-100 BHN

In-House Facilities

VAF Def-Aero Systems Private Limited has 4 sets of State of Art Heat Treatment Furnace which is totally automated with Scada controls. The solutionizing and quenching is done automatically and we have 4 sets of separate oven for Precipitation. Our Furnaces are highly accurate and reliable. The time vs temperature graph is auto generated and the print is attached along with the inspection report.

Based on Customer requirement, we do sampling inspection or 20% inspection or 100% inspection. The heat treatment section is equipped with a lab to test for mechanical properties like tensile strength, elongation and yield strength. The Size of our furnaces are 1500 X 1500 X 1500 and the maximum component that can be treated is 1500 X 1500 mm.

The Time vs Temperature graph for one of our heat treated component is as follows: