ALUMINIUM FINISHES

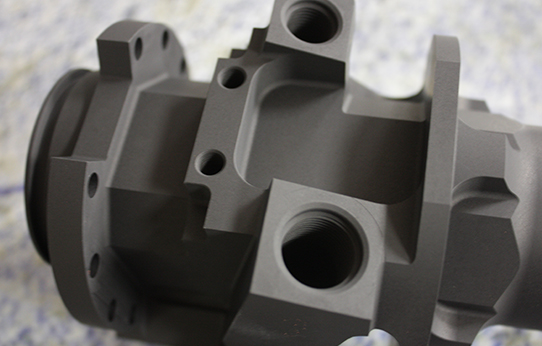

Cast aluminium finishes - Process of Casting

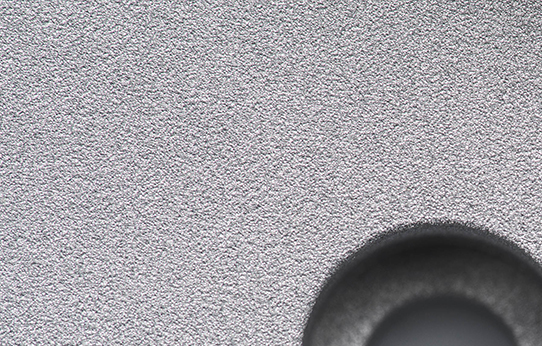

Anodised

Anodizing on cast aluminium gives different shades of grey. As the thickness increases the darkness increases. Automobile applications are usually anodized to 10-15 microns thickness which is known as clear anodizing. Marine applications are anodized upto 40 microns which are called as Hard anodizing.

Alodine/Chromating

Certain applications require corrosion resistance to chemicals. For such components, alodine coating offers a better corrossion resistance by hardening the surface. Aircraft parts are usually chromated. The process is done mostly after machining process. Sometimes, chromating is done before powder coating to act as a primer for the coating process.