Jargon of Radiography

Before we get into the description, it is better to know the jargon used in the process

- X-rays – are a type of electromagnetic radiation with high energy, very short wave length and thus can penetrate even through metals/alloys that are few centimetres thick.

- X-ray Film – consists of an gelatin emulsion containing ‘x-ray sensitive’ silver halide crystals, such as silver bromide or silver chloride and a flexible, transparent base.

Radiographic Testing with X-rays

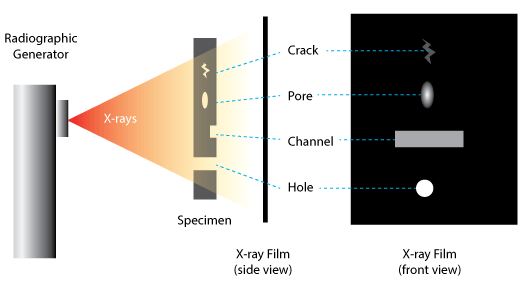

Radiographic Testing (RT) is a volumetric non-destructive evaluation (NDE) technique that helps to detect internal defects in castings, welds etc., which could not be detected by other NDE techniques like fluorescent penetrant, magnetic particle testing. This technique uses x-rays of short wavelength that pass through an object to be inspected which is placed between an x-ray generator and an x-ray film. As the rays pass through the object, they are absorbed variably across the object due to differences in thickness, density, presence of internal defects etc. These differences can be viewed as contrasting features on the film as darker areas indicating higher exposure and lighter areas indicating lesser exposure.

Film Processing

To view the details, the film needs to go through the following five steps:

- Development

- Stopping the development

- Fixing

- Washing

- Drying

Automatic processors are capable to process up to 150 films per minute and reduce film processing time from 4 hours to 1 hour.

Processed films are generally viewed on a light box.

Radiographic Interpretation - Castings

Interpretation of radiographs consists of three basic steps:

- detection

- interpretation

- evaluation.

Radiographic interpretation also depends on the lighting condition in the place of viewing, and the level of experience for recognizing various features in the image.

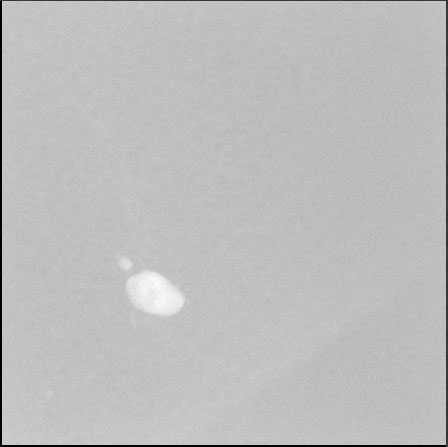

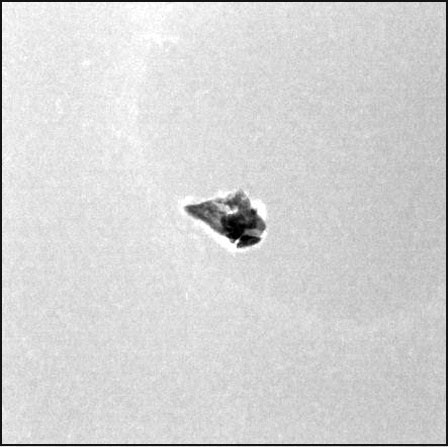

Following are the radiographs of various defects found in castings:

Sensitivity of radiograph = minimum size of the defect visible x 100 / part thickness

Other types of Radiography

Real-time radiography is an NDE method where an image is produced digitally instead of on a film. Due to this, the image will be quickly available for interpretation compared to conventional radiography.

Computed Tomography (CT) is an advanced, powerful NDE technique to analyse not only the defect shape as in conventional radiography, but also the dimensions, position and distribution of defects through 3-D images.

Application of X-ray Radiography in Industries

- Automotive

- Petrochemical

- Aerospace & Defence

- Marine

- Pressure vessels etc.

At VJP

The in-house facility has both film type, digital capability for testing aluminium alloy castings, machined castings of size up to 1000mm, wall thickness of up to 60mm, with an accuracy of up to 0.2mm. Castings of various grades are tested to the requirements of industry specifications like ASTM, AMS by well trained, highly qualified, certified NAS 410 Level-II inspectors.

Following are the available equipment:

- Bosello High Technology Digital X-ray system

- Film type X-ray system

- GE Automatic X-ray Film processor

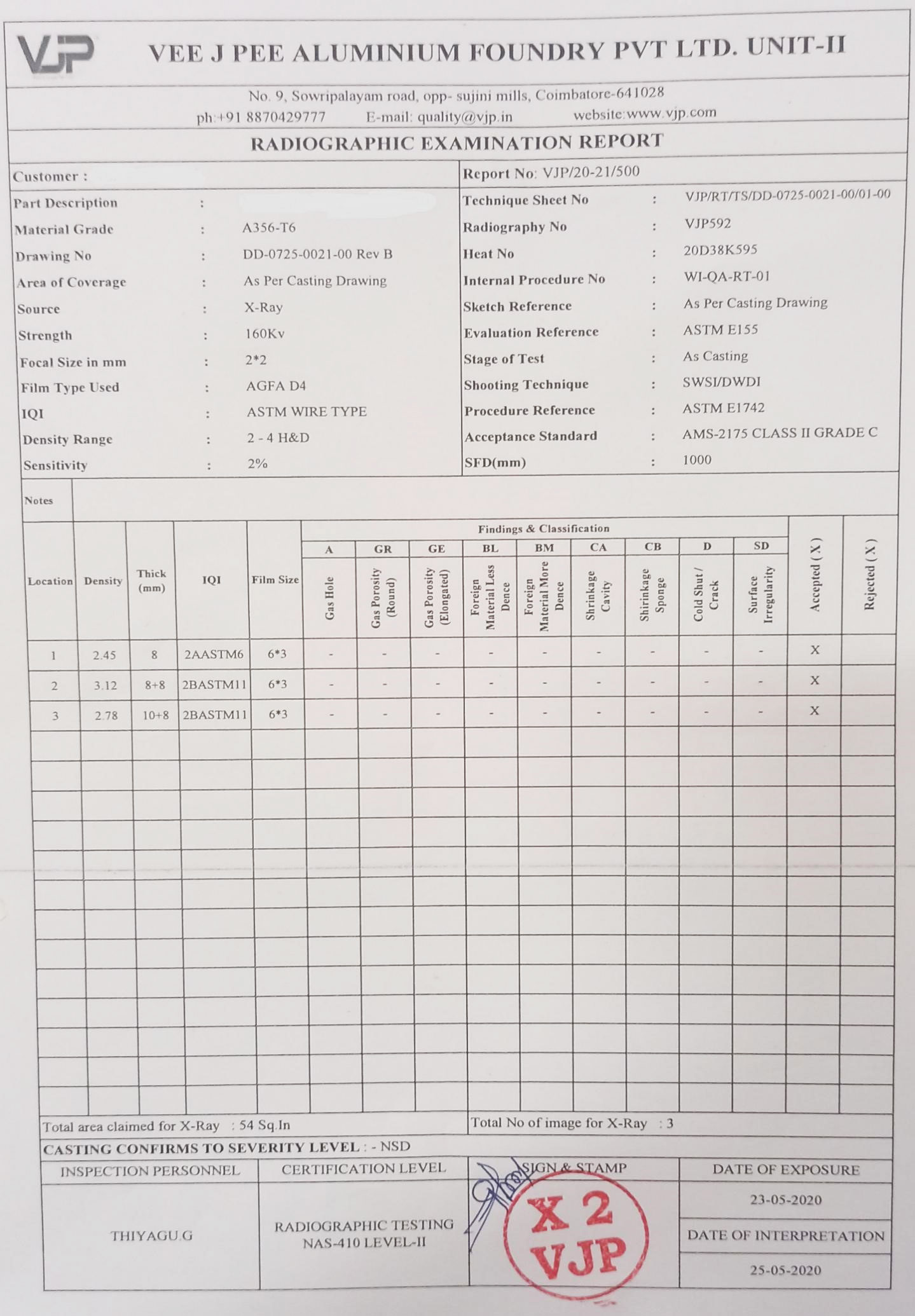

Sample Inspection Report